The rise of grid-forming batteries in the NEM

The retirement of synchronous generation is causing electricity grids worldwide to lose critical sources of system stability. Grid-forming (GFM) technologies will be essential to replace this capability and ensure electricity grids have the resilience to manage shocks during the transition.

Most existing inverter-based generators in the NEM use grid-following (GFL) inverters, which are built to maximise active power output into the grid. This inverter choice makes sense for intermittent technologies that can’t easily adjust their output. But as thermal generators retire, grids are left with fewer providers of inertia and system strength.

This article looks at the state of GFM in the NEM, one of the most advanced GFM markets. It explores what GFM is, how early projects have been funded, and the cost difference between GFM and GFL.

Executive summary:

- GFM batteries use advanced inverter controls to establish their own voltage waveform. Acting as a voltage source allows them to provide network support services.

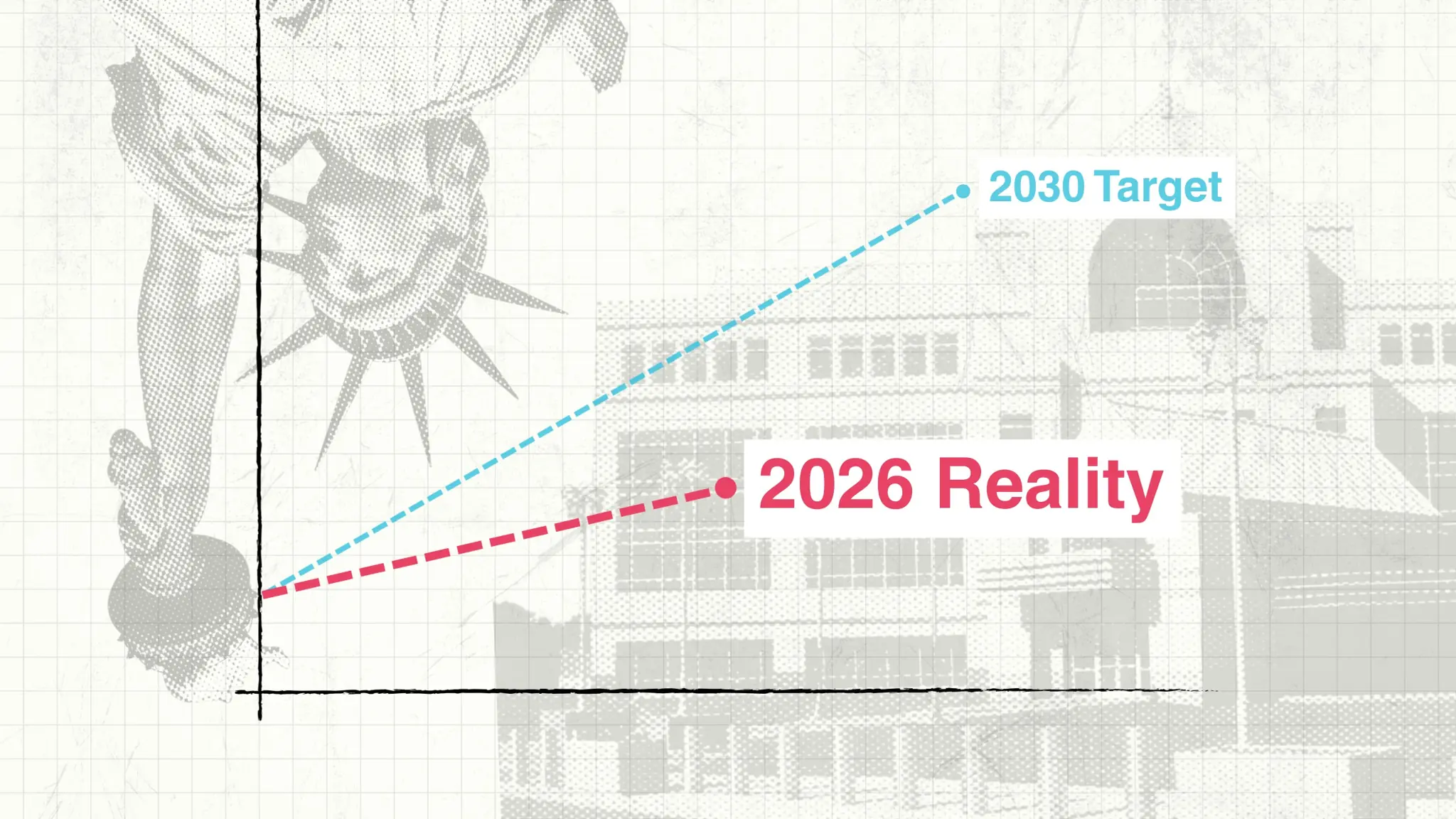

- Twelve GFM batteries are now operational in the NEM. ARENA and other government funding programs have backed the most of these to date.

- GFM batteries are increasingly being contracted to provide system services in the NEM. Three GFM batteries have been contracted to provide voltage support, synthetic inertia, and grid stability services

- The cost to build a GFM battery in the NEM is now virtually the same as GFL. GFM requires more rigorous testing, which makes that part of the process marginally more expensive.

What is a grid-forming battery?

Grid-following batteries maximise power output from a generator to the grid, but they don’t actively respond to the needs of the grid. These batteries can’t provide network support services like system strength or voltage control, which leaves them prone to curtailment during grid disturbances.

Grid-forming batteries use advanced inverter controls to establish and regulate voltage and frequency at their connection point. This enables them to respond to local grid conditions, supporting stability through services like voltage regulation, frequency control, and synthetic inertia.

GFM batteries allow for greater system support and operational flexibility

GFM batteries create their own voltage waveform instead of relying on the grid. Acting as a voltage source gives them capabilities that extend beyond energy delivery.

Key capabilities of grid-forming BESS include:

- Voltage and reactive power support: They can hold grid voltage steady and rapidly inject or absorb reactive power during disturbances. Measured in MVAr.

- Short-circuit level support: GFM batteries can deliver short bursts of high current during faults. This strengthens fault ride-through capability and supporting protection systems. Measured in MVA.

- Inertia response: GFM batteries provide synthetic inertia through their control systems, slowing the rate of change of frequency during disturbances. Measured in MW.s.

- Operate while islanded: GFM batteries can maintain stable operation of a local system even if separated from the main grid.

These capabilities allow GFM batteries to provide network support services that coal and gas generators have historically provided.

In the NEM, participation in these services does not typically interfere with energy or FCAS participation, as most are delivered through reactive power. Inertia relies on active power, but the amount of headroom required is small, and the impact on revenues is minimal.

Layering these services on top of regular revenue streams allows batteries to provide them much cheaper than other stability providers.

The Australian Energy Market Commission estimates the cost of providing inertia for different technologies as;

| Fixed cost ($/MW.s/year) | Variable cost ($/MW.s/hour) | |

|---|---|---|

| New synchronous condenser | $7,600 | $0.20-0.50 |

| New grid-forming BESS | $0-806 | $0.02 |

This positions GFM batteries as the lowest-cost providers of inertia in the future.

Government support has backed all grid-forming BESS to date

There are currently twelve operational GFM batteries out of 30 in the NEM. The original ARENA pilot program funded five of these projects, focusing mainly on low system strength areas in New South Wales and South Australia. The second ARENA program, the Large Scale Battery Storage Funding Round, supported the retrofit and commissioning of three grid-forming technology batteries, all of which are greater than 200MW.

This support helped de-risk the technology for developers and OEMs, allowing them to test GFM inverters and demonstrate their system security value. All operational GFM batteries to date have sourced inverters from Tesla, Power Electronics, or EPC Power.

State-based support for GFM batteries is also emerging. This is led by the Victorian Energy Innovation Fund, which has already committed $126 million towards two GFM projects: Koorangie and Terang.

Government funding extends beyond existing projects, with another four batteries in development: Liddell, Gnarwarre, Mortlake, and Terang.

Government funding has played a key role in deploying GFM technologies at early projects, but incentives are now shifting towards how the technology can provide long-term network support.

Three GFM batteries already hold contracts with Transmission Network Service Providers (TNSP), these are:

- Riverina and Darlington Point: contracted to provide voltage support services to Transgrid.

- Wallgrove: also contracted by Transgrid to deliver grid-scale Fast Frequency Response as a form of synthetic inertia.

- Koorangie: contracted to provide system strength services grid stability in north-west Victoria.

Although details of these network support contracts are confidential, they highlight the growing value of GFM capability.

The cost to build a GFM BESS is virtually the same as a GFL

GFM inverter costs have declined to the point where the premium for a GFM battery over a GFL is negligible in new projects. GFM systems in the NEM do require more testing to connect to the grid, which makes the commissioning process marginally more expensive.

By contrast, retrofitting grid-forming onto an existing project can cost up to 21x the additional cost of deploying GFM from the start. This makes it rational for developers to adopt GFM at the start of a project. However, the cost of retrofitting is still relatively small, averaging $12k/MW for a 250MW asset.

GFM batteries are moving from pilot projects to mainstream adoption in the NEM. Government funding supported the construction of early projects, but network agreements are now emerging as the next incentive. With no real cost difference between grid-forming and grid-following, choosing grid-forming is becoming the default path for new projects.

For those wanting to dive deeper, here’s a list of articles sharing lessons from existing GFM batteries.