Co-location: what is the impact on future battery revenues?

Co-location of batteries with solar or wind can reduce construction and maintenance costs, compared to a standalone battery. Constraints to the grid connection, however, limit battery trading strategies and reduce revenues.

So, how does co-location work, and do the cost savings offset lost revenues?

- Co-located batteries share a grid connection with a generator, which can limit their ability to export power.

- Export constraints mean that co-located batteries sometimes can’t follow optimal trading strategies - reducing revenues.

- Higher load factors and a flatter generation shape mean that revenue impacts are greatest for batteries co-located with wind.

- Reducing battery capacity relative to the generator reduces revenue impacts.

- Savings from a shared grid connection are likely to offset lost battery revenues in many scenarios, but additional savings may be required for projects co-located with wind.

Co-located batteries share a grid connection with a generator

A co-located battery shares a single grid connection with another asset. Typically this is a solar or a wind farm, which we will focus on here, but this can be other asset types.

Export constraints reduce revenue opportunities

As the battery shares a grid connection with a source of generation, its export capacity can be limited when generation is high.

Batteries typically cycle up to twice per day on the wholesale market, discharging during the morning and evening peaks when prices are highest. Co-located batteries may be unable to export at full power to capture these price peaks, as the grid connection is partially constrained.

Instead, optimizers must sell some of this power at a different time for a lower price. This decreases revenues compared to a standalone battery.

Co-located generation type has a big impact on battery operations

Wind and solar have different daily and annual generation profiles - constraining the grid connection at different times. Solar generation only constrains co-located batteries during peak daylight hours when prices are low. Wind, however, may significantly constrain batteries for several days at a time.

The maximum daily average generation for a solar farm was 26% in 2019. For wind, this was 92% - with 42 days above 70%. This means that optimizers of a solar co-located battery should almost always be able to fully discharge a battery, just sometimes at a lower price. However, at a wind co-located battery, there are days when they may not be able to profitably export enough power to complete two cycles.

This is particularly true during periods with high wind generation- such as during Storm Gareth in 2019. The average constraint on the grid connection caused by wind generation in this period would have averaged 85% across 4 days, with little variation.

The daily generation profile of solar means that at times with peak prices, solar generation averages only 9% of the export capacity, compared to 29% for wind.

Revenue impacts are greatest for batteries co-located with high load factor wind farms

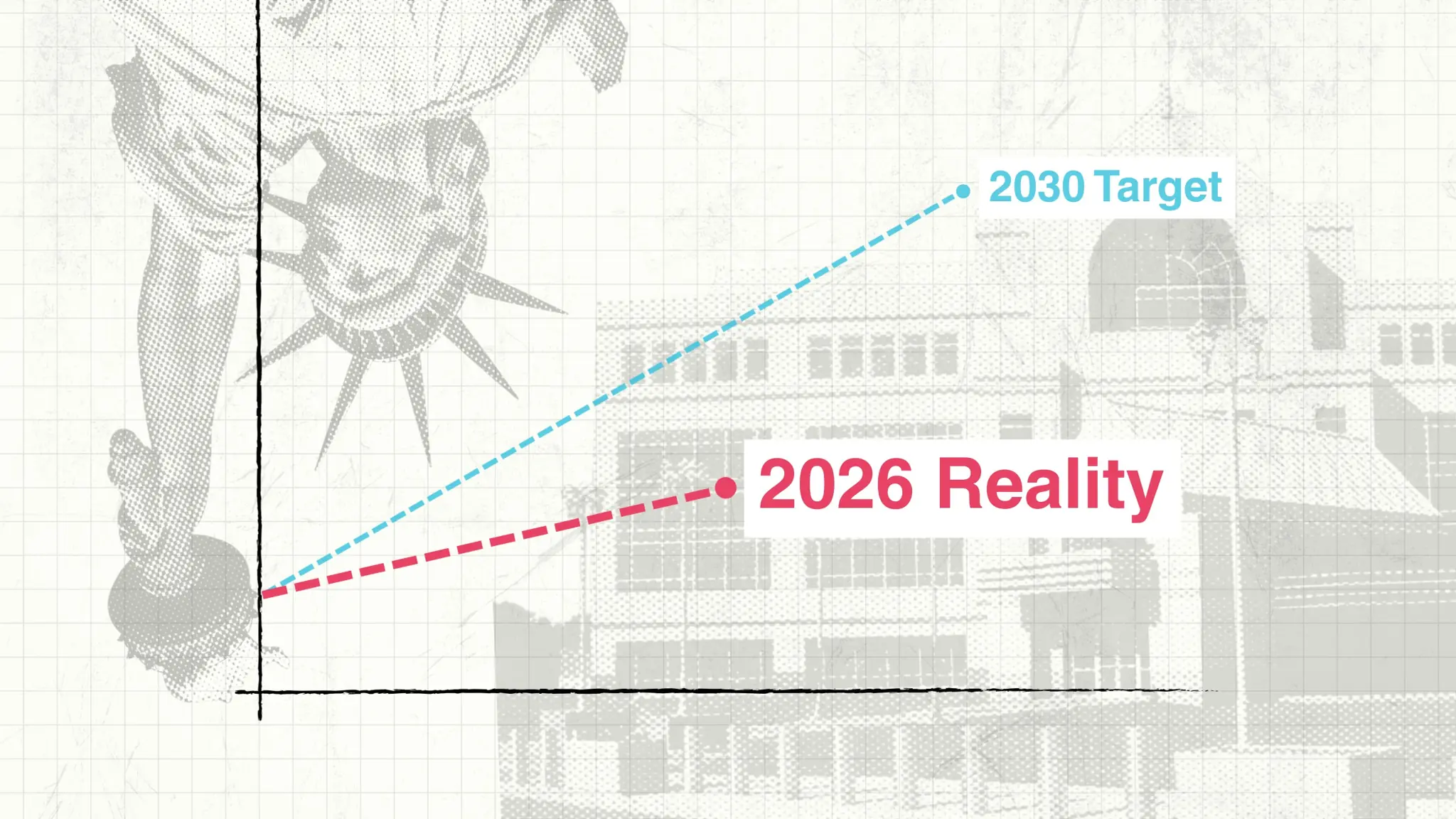

Wind load factors - the amount of power generated by the wind farm - vary significantly. The load factor for an onshore wind farm could vary between 25% and 40%, depending on its location and configuration. A 50 MW battery would earn 5% less than a standalone battery if co-located with a lower load factor wind farm, but 12% at a higher load factor site.

Already a subscriber?

Log in