ERCOT: The cost of unavailability for battery energy storage systems

ERCOT: The cost of unavailability for battery energy storage systems

In general, batteries that are available less often miss out on greater revenues - but this isn’t always the case.

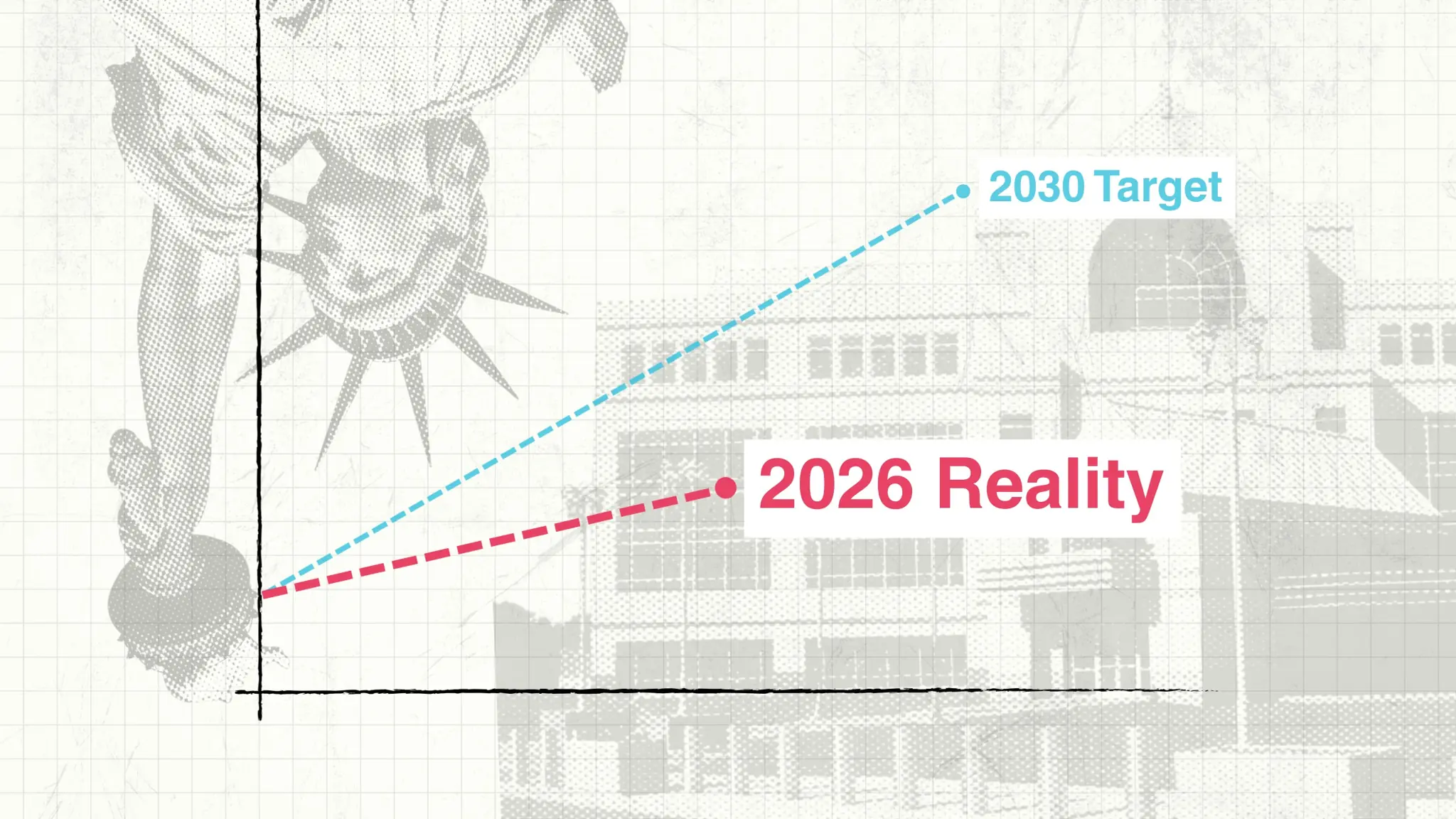

In 2023, battery energy storage systems in ERCOT were available for commercial operations 97% of the time (on average). And well-timed availability was crucial for maximizing revenues.

In fact, one system missed out on roughly $40,000/MW (around 20% of its potential annual revenues) - despite being available 96% of the year.

[Note: In this article, “availability” refers to the telemetered resource status of battery energy storage systems. Battery operators communicate this to ERCOT every 15 minutes.

For the sake of fair comparison, this article only looks at battery assets that began commercial operations in ERCOT before January 1st 2023.

To calculate “missed projected revenues”, we have used the Modo Energy ERCOT BESS Index - i.e. the average amount, per megawatt, that batteries earned - during the periods that each system was unavailable.]

Being available during high-revenue periods is vital for battery energy storage systems

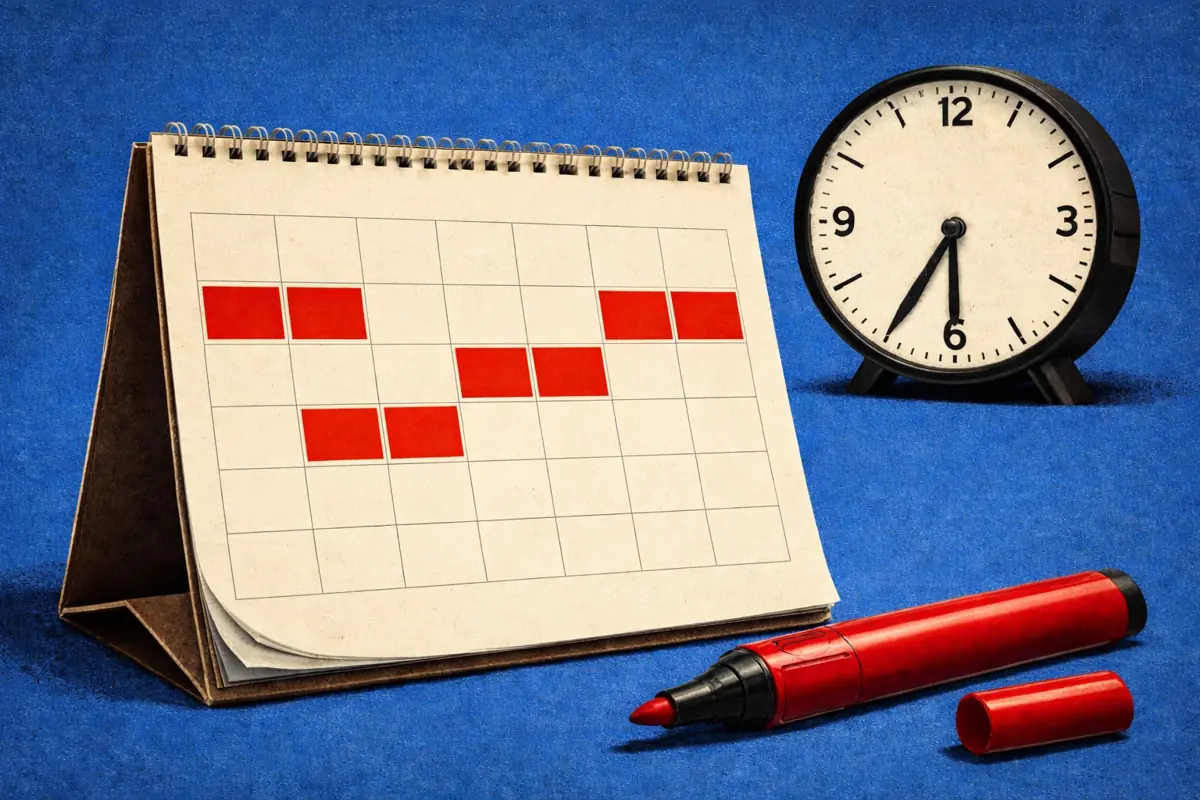

In general, the more often a battery is available, the more money it makes. However, because of price volatility in ERCOT, it’s vital to ensure that any periods of unavailability (e.g. for maintenance or testing, etc.) don’t clash with periods of potentially high revenues.

In 2023, 50% of all battery energy storage revenues in ERCOT were earned across just 13 days. Therefore, there was an outsized cost to being unavailable on any one of those days.

Some systems missed out on significant sums (>$7,500/MW/year), despite having high availability (>96%) over the course of the year. This is because those periods of unavailability were often unfortunately timed.

Battery energy storage systems are more likely to be available when prices are highest

In 2023, battery energy storage revenues in ERCOT were 10x higher in summer (June to September, inclusive) than during the rest of the year. This was due to huge price spikes during those summer months.

And, as you would expect, batteries were more likely to be available for commercial operations during these high-revenue periods.

- The average availability of batteries during the summer months (June to September, inclusive) was 98.7%.

- Immediately following those months, in October and November, average system availability fell to 95.9%.

This was likely due to some systems scheduling their downtime during periods when revenues were expected to be lower.

Though batteries in ERCOT were generally successful at avoiding downtime during high-revenue periods, overall availability was not consistently 100% throughout the summer. So, what was the actual cost of unavailability during high-revenue days?

Benchmarking Pro ERCOT subscribers can dive into a couple of individual case studies below.

Case studies: What was the actual cost of unavailability for individual battery energy storage systems?

As highlighted above, revenues for some battery energy storage systems were hit particularly hard by periods of unavailability.

Let’s take a look at two systems in particular:

Already a subscriber?

Log in