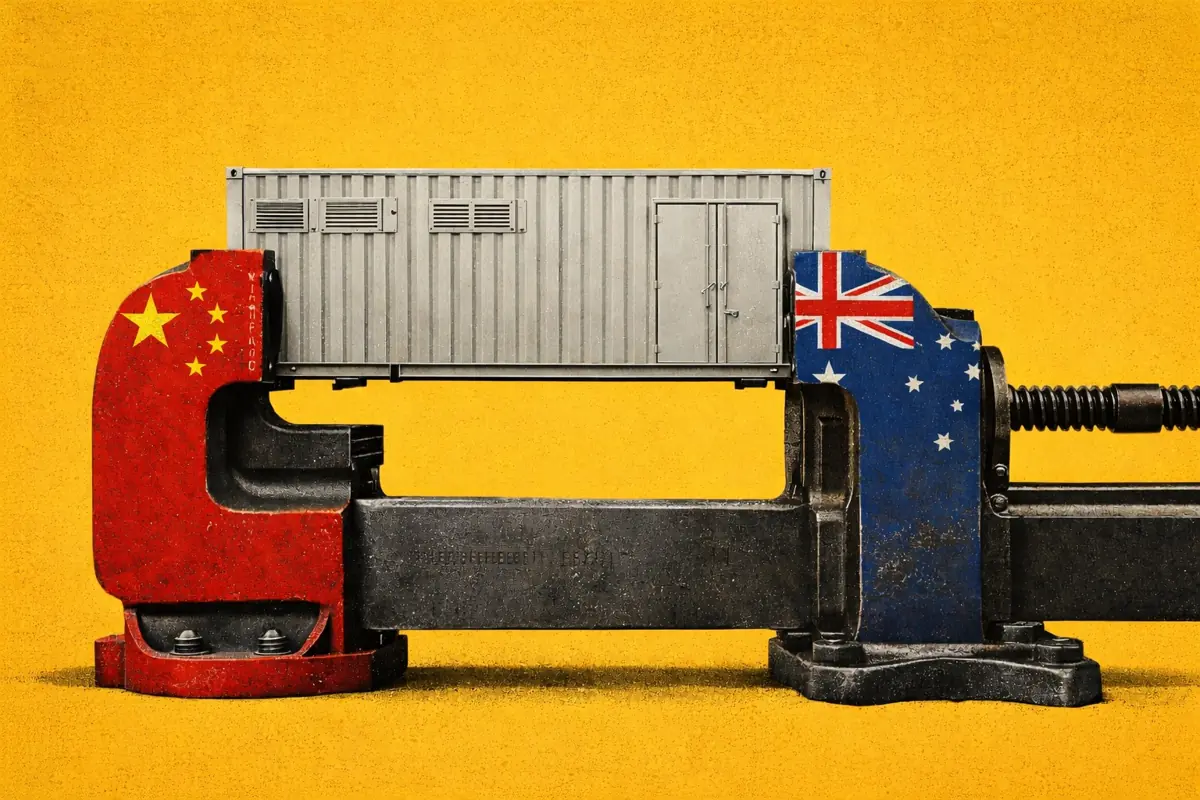

How much does it cost to build a battery energy storage system in 2024?

How much does it cost to build a battery energy storage system in 2024?

What’s the market price for containerized battery energy storage? How much does a grid connection cost? And what are standard O&M rates for storage?

Finding these figures is challenging. Because of this, Modo Energy surveyed the battery community - to produce this battery cost benchmark.

If you finance, own, or develop battery energy storage systems, you can use this data to support procurement and sense-check financial models.

To produce this benchmark, Modo Energy surveyed various market participants in Great Britain. We received 30 responses, covering 2.8 GW of battery energy storage projects - with commissioning dates from 2024 to 2028.

Due to the anonymous nature of the survey, we have not mentioned the names of the specific projects included in this analysis. Instead, we have focused on general cost trends - so you will find data on the following:

- Total project costs.

- How containerised BESS costs change over time.

- Grid connection costs.

- Balance of Plant (BOP) costs.

- Operation and maintenance (O&M) costs.

- And the time taken for projects to progress from construction to commercial operations.

Other variables add costs to projects. For the sake of simplification, this survey covers capital expenditure (CAPEX) costs. For example, some costs that aren’t covered in this analysis include:

- Developer premiums and development expenses - depending on the project's attractiveness, these can range from £50k/MW to £100k/MW.

- Financing and transaction costs - at current interest rates, these can be around 20% of total project costs.

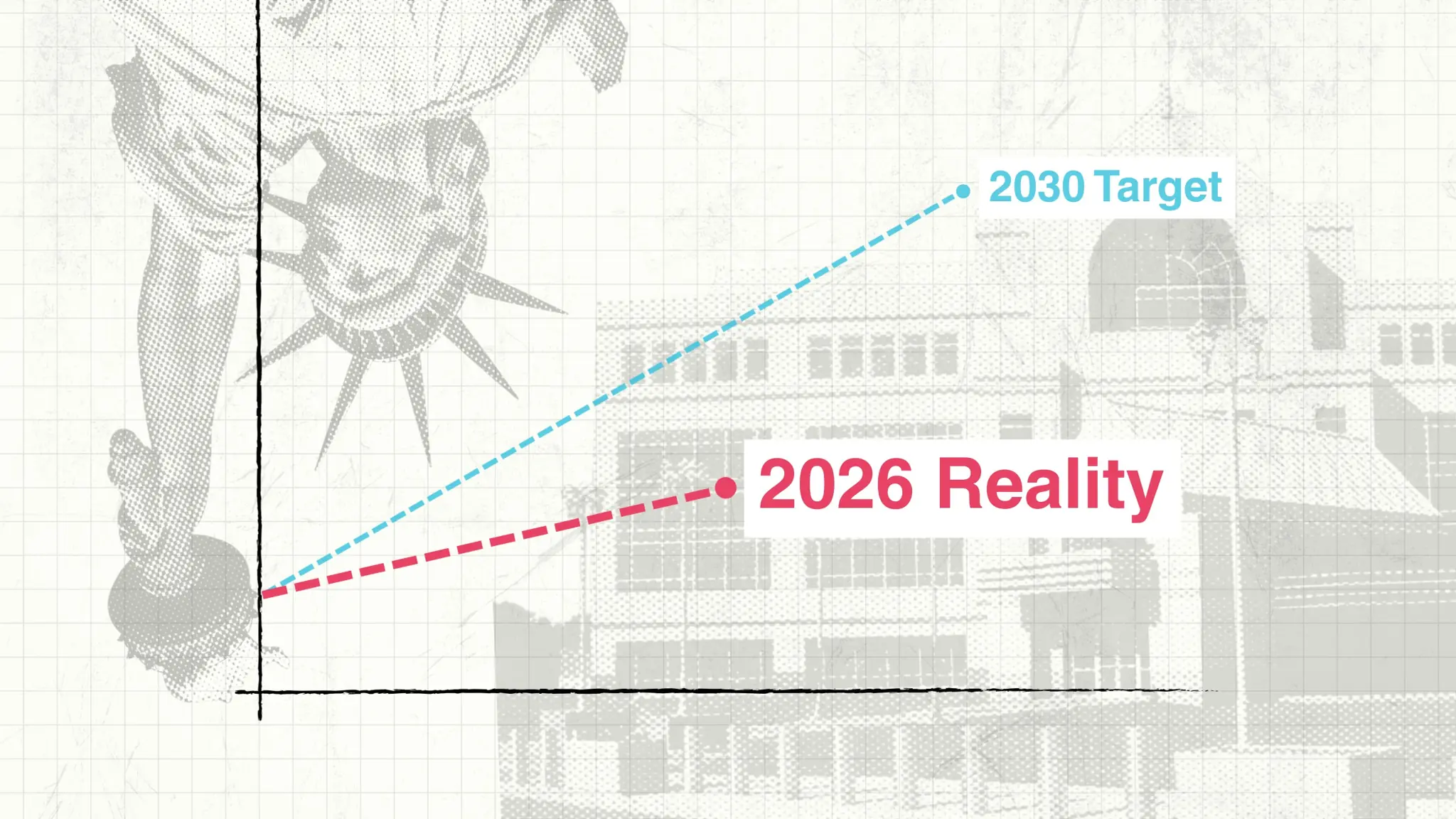

1) Total battery energy storage project costs average £580k/MW

68% of battery project costs range between £400k/MW and £700k/MW.

When exclusively considering two-hour sites the median of battery project costs are £650k/MW.

Already a subscriber?

Log in